Panelable multifunction weight display 48×96 mm. DW-MI

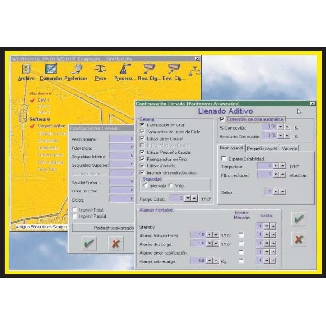

This indicator allows the control of various processes in the field of industrial weighing such as:

- Additive and subtractive filling.

- Integration.

- Bulk-weighing.

- Happens – Does not pass.

- Weight – Tara.

CHARACTERISTICS

- Load cell inputs with Sigma-Delta A / D converter 24 bits.

- Display 7 segments of 6 digits, 14 LED indicators.

- 2 Serial channels: 1 RS232 and 1 RS422 or RS485 optoisolated.

- Keyboard 8 keys for programming and manipulating the indicator.

- 4 Optoisolated PNP or NPN entries.

- 115Vac power supply / 220 Vac.

- 4 Potential free contacts (Relays).

- Dimensions: 48 x 96 x 139 mm.

Choices

- 2º Canal serie RS232.

- USB communication 2.0.

- Opto-isolated analog output: 0-20 mA, 4-20 mA (only when powered at 24Vdc).

- WIFI communication.

- 24Vdc power supply.

| REFERENCE | DESCRIPTION |

|---|---|

| FillerAdd | Additive filling, bagged: 1 product up 3 flow rates, download and alarms. |

| FillerAddAdv | Additive filling, bagged: 1 product up 2 flow rates, download, alarms and 10 selectable programs. |

| FillerMan | Fill, manual bagging: indicates Defect - Correct - Over weight. |

| FillerSub | Subtractive filling: 1 product up 3 flow rates, recharge and alarms. |

| FillerAso | Associative filling: 1 product up 3 flow rates, download and alarms. |

| Bulk | Bulk Weighing (continuous weighing by cycles: Until 3 flow rates, download, alarms, ticket. |

| Check | Happens- Does not pass: Check if a weight is within a range of values. |

| Quality | QA: Verification of a batch of prepackaged product, based on RD723-1988 / OIML R87 (quantity of product in prepackaged). |

| Limits | Limits, alarms, tote, dynamometer: Until 4 weight limits, configurable inputs, variable printing, max memory, minimum, peak-peak. |

| Integra | Belt weighing: Integration, tote, slogans, flow hour, etc... |